PerfectSeal Constant Seating Stress Gaskets

Leakage from gasketed flange joints in process piping systems not only results in product loss and increased maintenance requirements, but may also cause consequential damage to equipment, components, and the environment, as well as affecting plant reliability and availability.

In some industries, research has shown that the direct O&M cost impact due to leakage is well over $1 million dollars per year, per plant. Research also clearly indicates that incorrect initial gasket seating stress or gasket relaxation over time (resulting in loss of gasket seating stress) are the principal causes of most leakage events. The patented PerfectSeal constant seating stress gasket is the world's first and only gasket designed to achieve the desired seating stress automatically on installation, and to maintain that stress in-service over time, regardless of system thermal cycles, high-vibration, or other challenges to joint leaktightness. Our innovative visual compression indicator enables the assembly technician to immediately determine when the correct gasket compression has been achieved.

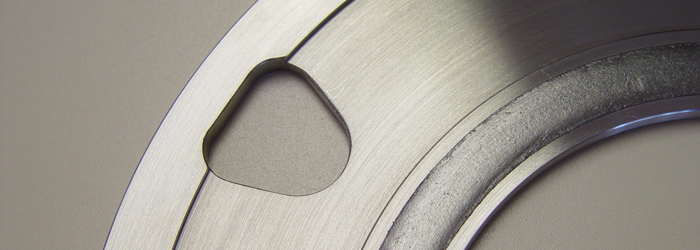

Our PerfectSeal line of constant seating stress gaskets are available in a number of standard designs to suit various flange configurations, including various pipe flange styles and valve body-to-bonnet joints. In addition, JJENCO produces custom gasket designs, such as double-gasket configurations, to address specific sealing issues for unusual gasketed joints. All JJENCO PerfectSeal gaskets incorporate our key constant seating stress principles of achieving the correct stress on installation and eliminating creep relaxation of the sealing material in-service.

The gasket carrier ring for our constant seating stress gaskets are normally fabricated from 304/316 stainless steels, however other suitable materials can be used to address specific requirements. Likewise, our standard sealing elements are fabricated from nuclear-grade (high purity) expanded graphite, however other graphite grades or alternate compressible sealing materials (PTFE, compressed fiber, vermiculite, etc) are also available to meet specific performance goals.

Due to its unique technical features and customizable design, with the PerfectSeal gasket anyone can obtain a ‘perfect seal’ every time! Perfect for critical applications or locations where technican training or available assembly tools may be less than ideal.